Bolted Steel Tanks for Industrial Effluent Storage

Product Overview

Bolted Steel Tanks for Industrial Effluent Storage: A Comprehensive

Guide

Industrial effluent storage requires robust, scalable, and

environmentally compliant solutions. Bolted steel tanks have

emerged as a top choice for industries worldwide due to their

adaptability and long-term reliability.

Why Choose Bolted Steel Tanks for Industrial Effluent?

1. Durability in Harsh Environments

Bolted steel tanks are engineered to withstand corrosive chemicals,

extreme temperatures, and heavy loads—common challenges in

industrial effluent storage. High-quality coatings and galvanized

steel options further enhance resistance to degradation, ensuring a

lifespan exceeding 30 years with proper maintenance.

2. Modular Design for Scalability

Unlike monolithic concrete tanks, bolted steel tanks are

prefabricated and assembled on-site. This modularity allows rapid

deployment and easy expansion. For instance, industries can

incrementally add tank panels to meet growing effluent volumes

without disrupting operations.

3. Cost-Effectiveness

The reduced labor and construction time of bolted tanks translate

to lower upfront costs. Sichuan Mondes Green Technology Co., Ltd.,

a leader in the industry, emphasizes budget-friendly installations

while maintaining compliance with safety standards.

4. Environmental Compliance

These tanks are designed to prevent leaks and contamination.

Customizable liners (e.g., epoxy or GFS) can be added to meet

regulatory requirements for hazardous effluent storage.

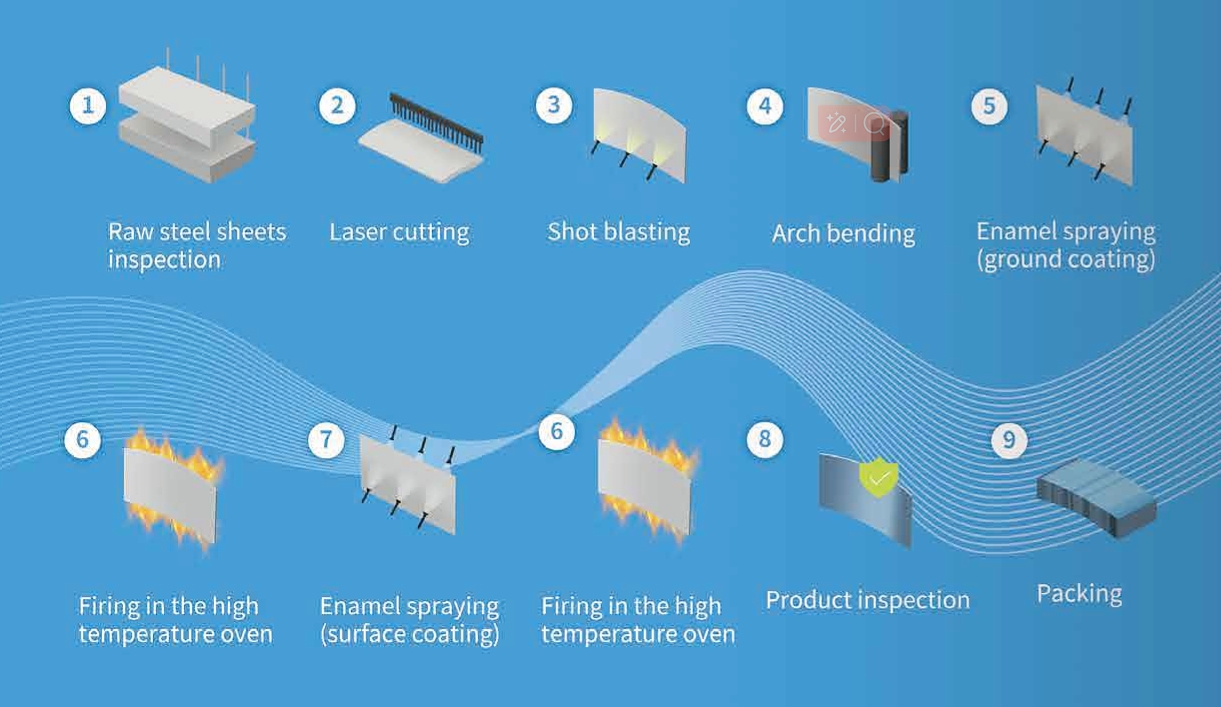

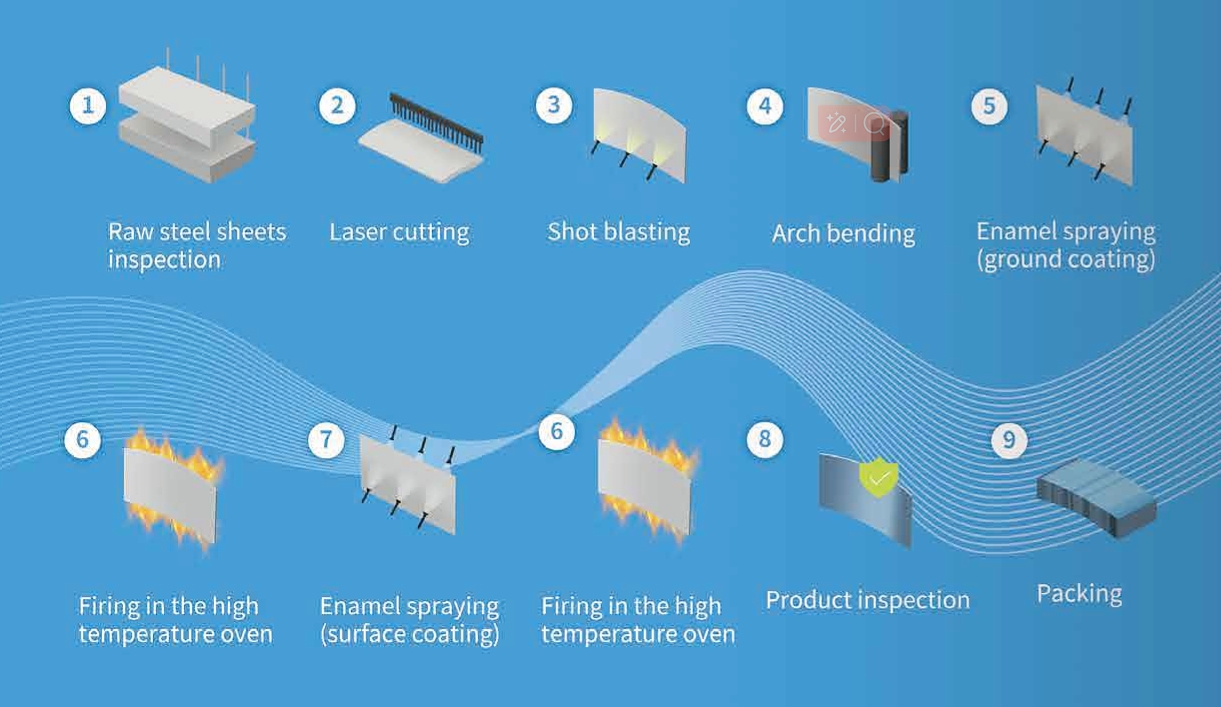

Manufacturing Procedure

Key Applications of Bolted Steel Tanks in Effluent Management

Industrial sectors leveraging this technology include:

- Chemical Manufacturing: Storing acidic or alkaline wastewater.

- Mining: Handling slurry and tailings.

- Food Processing: Managing organic waste streams.

- Oil & Gas: Safeguarding produced water and drilling fluids.

Comparative Analysis: Bolted Steel vs. Alternatives

To illustrate the superiority of bolted steel tanks, consider the

following table:

Feature Bolted Steel Tanks Concrete Tanks Polyethylene Tanks

Installation Time 2–4 weeks 8–12 weeks 1–2 weeks Lifespan 30+ years

20–25 years 10–15 years Customization High Low Moderate Corrosion

Resistance Excellent Moderate High Cost per 10,000 Gallons 15 , 000

– 15,000–25,000 30 , 000 – 30,000–50,000 8 , 000 – 8,000–15,000Feature Bolted Steel Tanks Concrete Tanks Polyethylene Tanks

Installation Time 2–4 weeks 8–12 weeks 1–2 weeks Lifespan 30+ years

20–25 years 10–15 years Customization High Low Moderate Corrosion

Resistance Excellent Moderate High Cost per 10,000 Gallons 15 , 000

– 15,000–25,000 30 , 000 – 30,000–50,000 8 , 000 – 8,000–15,000Feature Bolted Steel Tanks Concrete Tanks Polyethylene Tanks

Installation Time 2–4 weeks 8–12 weeks 1–2 weeks Lifespan 30+ years

20–25 years 10–15 years Customization High Low Moderate Corrosion

Resistance Excellent Moderate High Cost per 10,000 Gallons 15 , 000

– 15,000–25,000 30 , 000 – 30,000–50,000 8 , 000 – 8,000–15,000Feature Bolted Steel Tanks Concrete Tanks Polyethylene Tanks

Installation Time 2–4 weeks 8–12 weeks 1–2 weeks Lifespan 30+ years

20–25 years 10–15 years Customization High Low Moderate Corrosion

Resistance Excellent Moderate High Cost per 10,000 Gallons 15 , 000

– 15,000–25,000 30 , 000 – 30,000–50,000 8 , 000 – 8,000–15,000

| Feature | Bolted Steel Tanks | Concrete Tanks | Polyethylene Tanks |

|---|

| Installation Time | 2–4 weeks | 8–12 weeks | 1–2 weeks |

| Lifespan | 30+ years | 20–25 years | 10–15 years |

| Customization | High | Low | Moderate |

| Corrosion Resistance | Excellent | Moderate | High |

| Cost per 10,000 Gallons | 15,000–25,000 | 30,000–50,000 | 8,000–15,000 |

Note: Costs vary based on design complexity and regional labor

rates.

FAQs: Addressing Common Concerns

Q1: How do bolted steel tanks prevent leaks in corrosive

environments?

A: Advanced sealing systems (e.g., double-seal gaskets) and

corrosion-resistant coatings are applied during manufacturing.

Regular inspections further ensure integrity.

Q2: Can these tanks be relocated if facility layouts change?

A: Yes! Their modular design allows disassembly and reassembly at

new sites, minimizing waste and costs.

Q3: What maintenance is required?

A: Annual inspections for coating wear, bolt tightness, and liner

condition are recommended. Thompson Tank offers lifetime technical

support for its installations.

Q4: Are bolted steel tanks suitable for high-salinity effluent?

A: Absolutely. Stainless steel variants or specialized coatings

(e.g., zinc-aluminum) are available for such scenarios.

Future Trends in Effluent Storage Technology

The industry is shifting toward smart tanks equipped with IoT

sensors to monitor fluid levels, pH, and structural stress in real

time. Pairing bolted steel’s physical robustness with digital

oversight enhances operational efficiency and regulatory

compliance.

Conclusion

Bolted steel tanks offer a versatile, cost-efficient, and durable

solution for industrial effluent storage. By partnering with

experienced providers like Thompson Tank & Construction

Inc.—licensed across 17 U.S. states—industries can achieve

compliance and scalability without compromising safety.

For tailored solutions, consult professionals to evaluate

site-specific needs, from material selection to regulatory

adherence.

Need more details? Please feel free to contact us:

Email: richie@scmondes.com, WhatsApp: +86 15902825209

Product Show